Compact, heatless compressed air adsorption dryers with activated carbon stage for industrial applications and volume flows up to 86 m³/h and dew points of -25°C to -70°C.

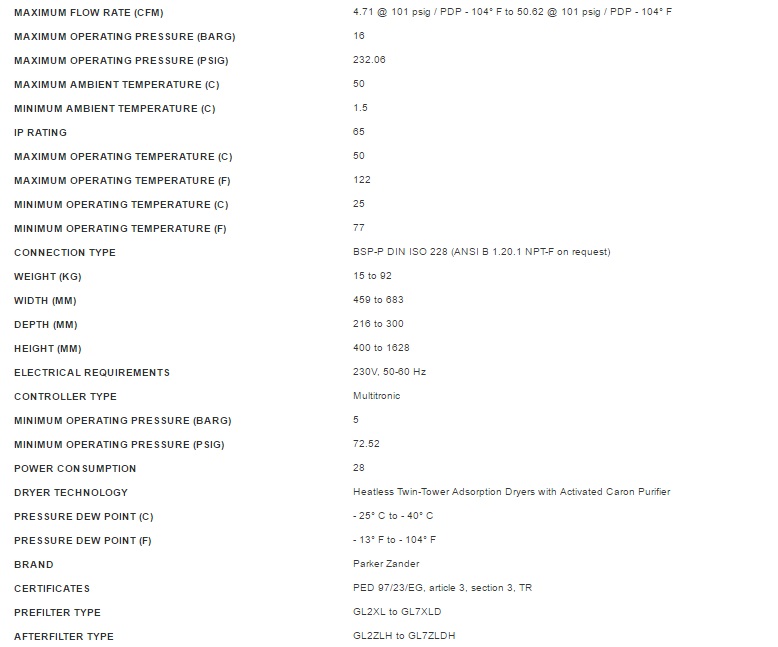

The Parker Zander KA-MT 1-8 range of heatless adsorption dryers with integrated activated carbon stage are designed to dry industrial compressed air reliably and efficiently down to a pressure dew point of -70°C and to a remaining oil content of 0,003 mg/m³. The units are compact and are designed to be installed free-standing or wall mounted. Compressed air dryers of the KA-MT series come with an integrated activated carbon stage for the removal of oil vapours and pre- and after filtration of the GL series, they are capable of volume flows up to 86 m³/h in a system operating at 7 barg (100 psig).

Features

• Pressure dew point down to -70 °C

• Volume flows up to 86 m³/h @ 7 barg (100 psig)

• Pre- and after filters installed as standard

• Fully dewpoint dependent control is possible as an option

• Remaining oil content of 0,003 mg/m³

Benefits

• Highest quality air

• Energy efficient

• Dry air means zero corrosion

Operation

Compressed air first enters the GL pre-filter. Next, the air flows into one of two adsorption vessels both filled with molecular sieve – a renowned drying-agent, where the compressed air is dried. During the drying cycle, the second vessel undergoes regeneration. At the start of the cycle, this vessel exhausts to atmosphere, and a small portion of dried compressed air passes through the adsorption bed, transporting the humidity out. When the regeneration process is complete, the regenerated vessel is re-pressurised in readiness to repeat the drying process. After being dried in one of the vessels filled with desiccant, the air enters the activated carbon purifier stage, where oil vapour and odour is removed. Finally the clean, dry air exits via a GL after-filter preventing the migration of particles into the downstream compressed air network. KA-MT 1-8 adsorption dryers operate a fixed, timed, changeover cycle between the two drying vessels.

Energy Savings

Where an application calls for a unit able to cope with variations in operating pressure and load, the installation of a dew point sensor at the outlet of the dryer is available as an option. In such an operating mode, the changeover cycle between vessels only takes place when required, and is dependent on the required dew point being achieved. Only upon reaching this adjustable set dew point, does changeover to the regenerated vessel occur. This feature enables the drying phase to be lengthened and thus avoids the unnecessary use of purge air for regeneration and consequently provides energy savings.

Compressed air can be selectively dried to meet a dew point of -25°C down to -70°C.

For more information or a detailed discussion about your specific requirements please contact Parker or an authorised Parker distributor.