Activated carbon adsorbers for volume flows up to 6100 m³/h for industrial compressed air treatment applications

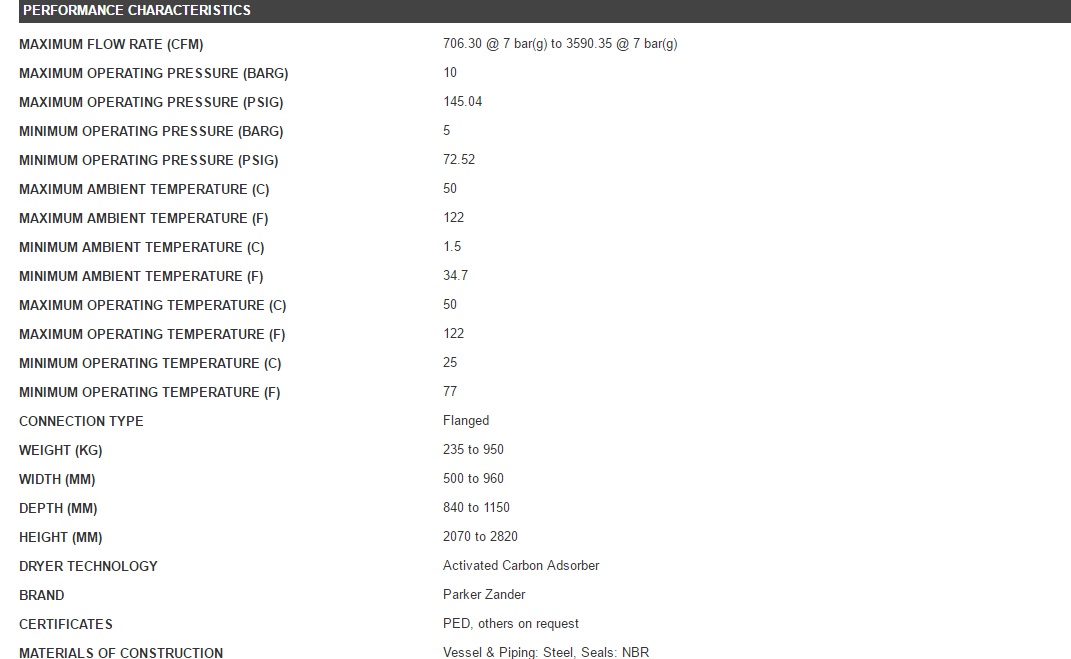

The Parker Zander AK 120-600 range of activated carbon adsorbers are designed to purify pre-dried industrial compressed air down to a remaining oil content of 0,003mg/m³. The units can be installed free-standing or on a frame. They come equipped with oil indicator and pressure gauge and are capable of volume flows up to 6100 m³/h in a system operating at 7 barg (100psig). Matching pre- and after-filters have to be ordered separately.

Features

• Volume flows up to 6100 m³/h @ 7 barg (100psig)

• Maximum operating pressure 10 bar(g)

• Oil indicator, pressure gauge and after-filter included

Operation

Pre-dried compressed air flows from top to bottom through a single vessel containing activated carbon. Any remaining oil aerosols and oil vapours including odours and tastes are removed by the active surface area of the highly porous activated carbon to produce high quality, clean compressed air. Using an oil-indicator tube, quality checks can be carried out periodically.

Please note: The lifetime of the activated carbon filling can vary and is dependent on the contamination type and quantity and also on the humidity of the compressed air.

For more information or a detailed discussion about your specific requirements please contact Parker or an authorised Parker distributor.